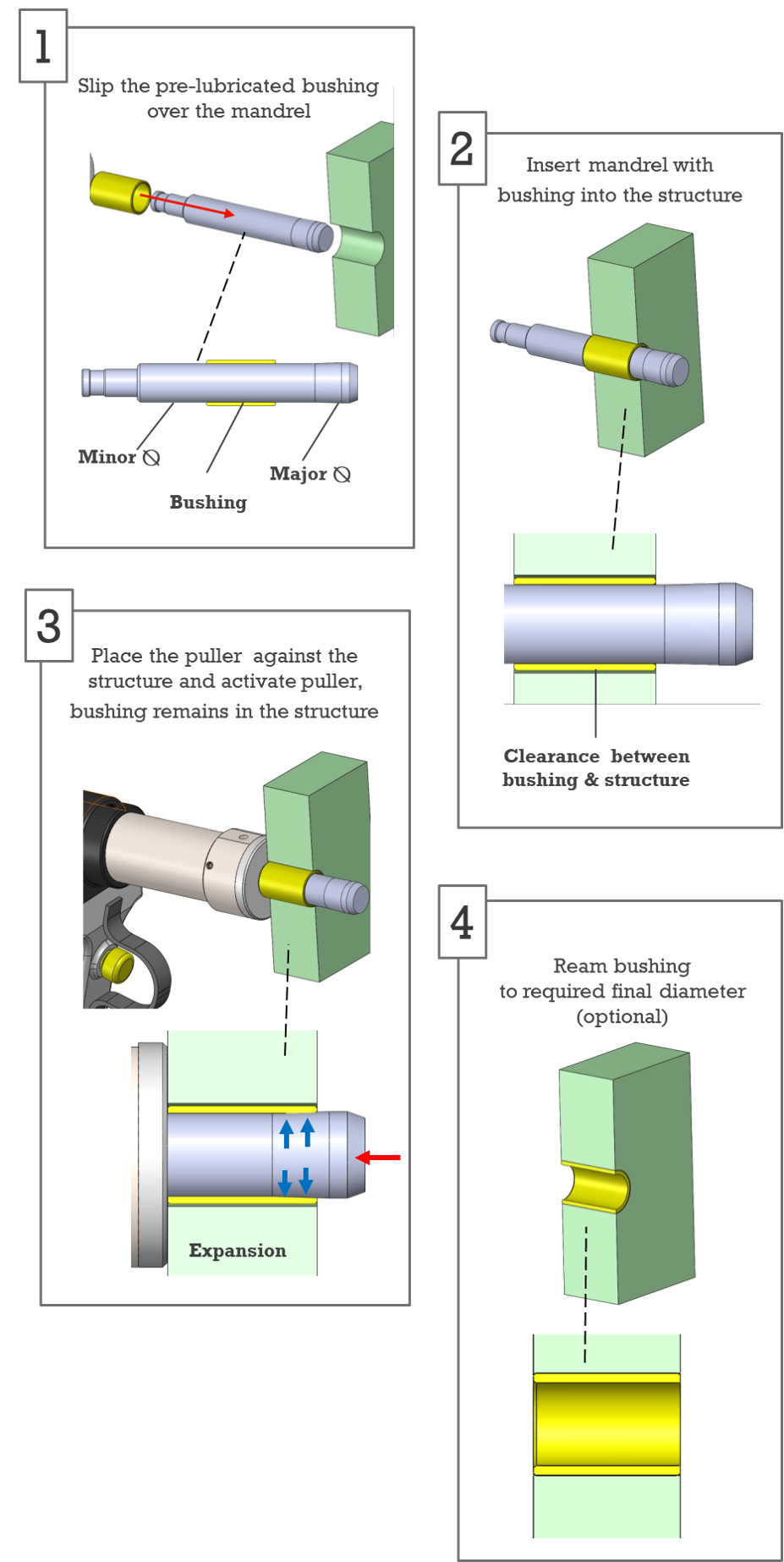

Expanded bushing (EB) simultaneously coldworks the material around the hole, and provides a high interference fit

Expanded bushing offers several advantages :

- Improved Fatigue Life

- Fatigue life superior to press or shrink fit installations

- One-Sided Operation

- Process accomplished within seconds

- Corrosion Resistance

- Protective coatings are not damaged during installation

- High Torque and Pushout Resistance

- Greater resistance to rotation and pushout compared to conventional installation methods

- Installation is Safer and Quicker

- Cryogenic fluid not required

Expanded bushings can be used for most bushing installations. Bushings are available in a number of materials and configurations:

Configurations

- Large range of Bushing inside diameter : from 10mm to more than 100 mm

- Bushing geometry : Straight and flanged - Lube grooves and holes

- Bushing material: Bronze, Titanium, Steels, Beryllium-copper, Aluminium, Nickel...

- Parent material: Aluminum, Steel, Titanium...

Contact CAPAERO for assistance with your specific application requirements.

Anti-fretting coating

CAPAERO is able to design bushings with an anti-fretting coating (Greencoat). This is widely used on helicopter applications.